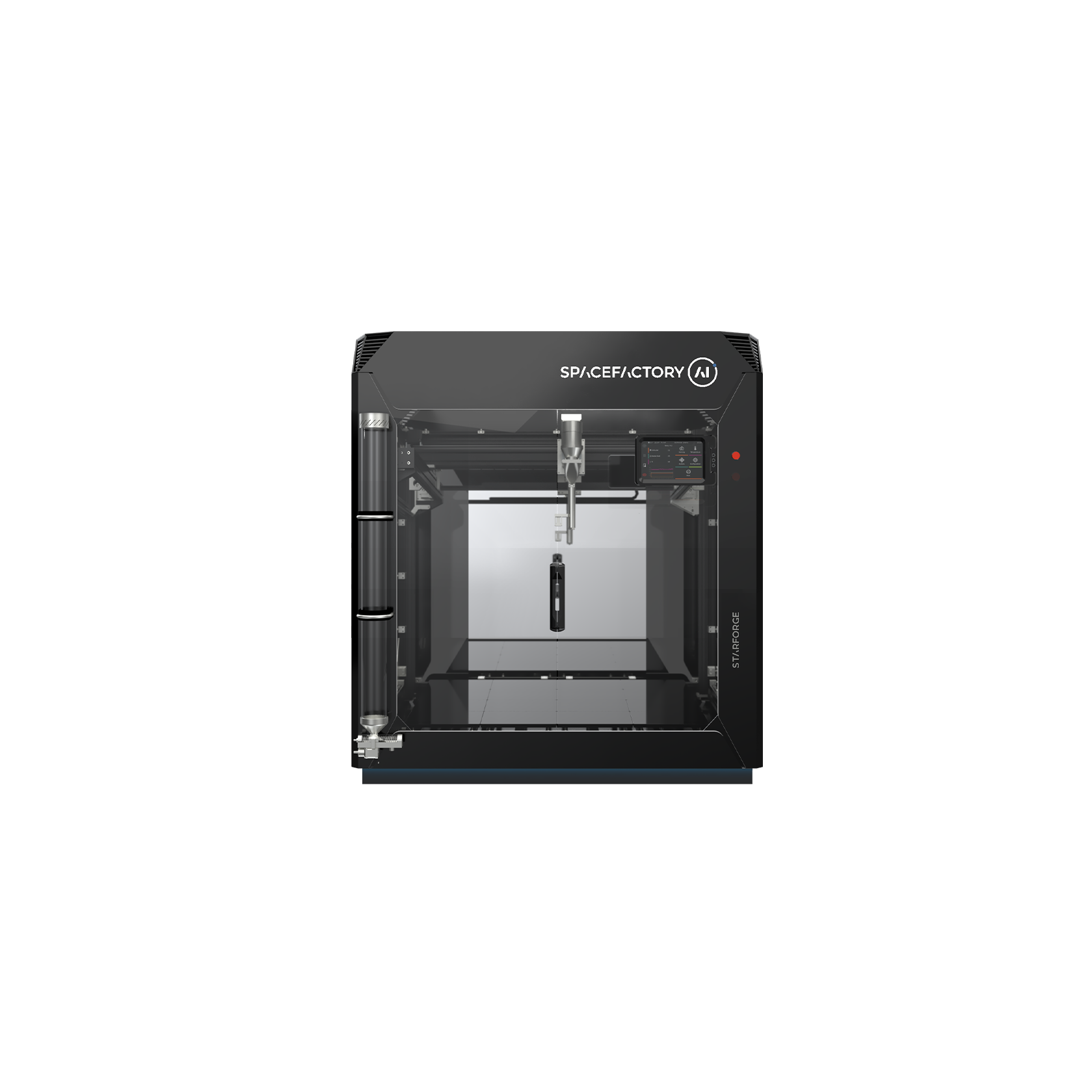

STARFORGE

Large Format Additive System

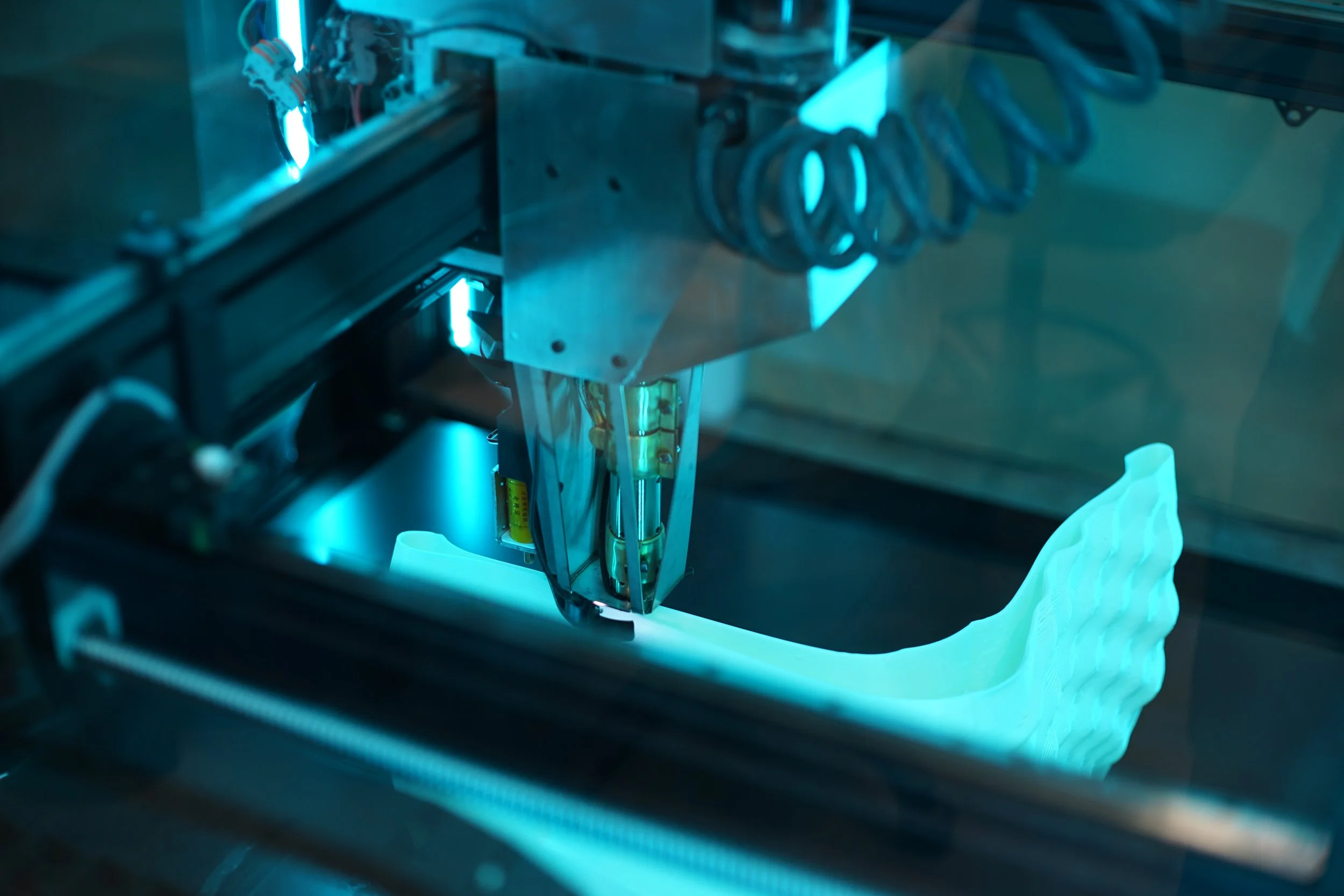

Step into the future with Starforge—a large format additive system powered by cutting-edge fused granular fabrication (FGF) technology. This revolutionary platform boasts a massive build envelope, unlocking extraordinary project dimensions and broadening the realm of possibilities. Equipped with a robust pellet extruder that proficiently processes high-fill polymer composite materials—including glass, carbon, and basalt fibers—Starforge's unmatched versatility ensures that even your most ambitious projects are not only possible but also practical.

Starforge distinguishes itself by offering expansive capabilities and premium hardware at an excellent price point. Featuring high-end components such as stainless steel ball screws, Teknic servo motors, and a tiled glass heated print bed with multi-zone control, Starforge delivers premium performance at a fraction of the cost of other large format systems. The system is fed by SpaceFactory's patent-pending pellet handling technology, which streamlines the manufacturing process and boosts both efficiency and reliability. Representing an astute investment, Starforge offers substantial benefits and superior functionality for those seeking entry into advanced capabilities in additive manufacturing.

Effortless Accuracy

High Precision. Effortless Operation.

Starforge was designed from the ground up to embody "effortless accuracy"—achieving precision without complexity. With an impressive 0.3% part tolerance, Starforge combines high performance with straightforward usability. Fully compatible with G-code from open-source slicers like Prusa and Cura, and running on Klipper firmware, it ensures a smooth transition from desktop 3D printing to large-scale operations. Supported by a vast user community and extensive online resources, Starforge’s open-source architecture feels familiar and seamless, making large-scale 3D printing as intuitive as ever.

SPECIFICATIONS

Starforge features a highly modular design in basic configurations of tall, long, and cube with a build volume ranging from over 36” up to 100” (950-2600 mm) along any axis. Standard features include a multi-zone heated glass print bed for printing materials up to 300 C.

-

Pellet extruder

Heated glass bed

Auto-quad leveling

Mesh leveling

Vacuum delivery system

Touch screen

-

Build Volume: 1000 mm x 1000 mm x 1600 mm

Overall Dimensions: 1630 mm x 1630 mm x 2460 mm

Weight: 560 kg

Throughput: 3.4 kg/hr (7.5lb/hr)

Print Velocity: 200mm/s

Power: 208V 3-Phase AC 30A

Bed temperature: 100°C (212°F)

Print Temperature: 280°C (536°F)

MODELS

-

T200

Build Envelope - W: 950 L: 1050 H: 1600 (37” x 41” x 63”)

Frame Size - W: 1500 L: 1500 H: 2000 (59” x 59” x 79”)

T250

Build Envelope - W: 950 L: 1050 H: 2100 (37” x 41” x 83”)

Frame Size - W: 1500 L: 1500 H: 2500 (59” x 59” x 98”)

T300

Build Envelope - W: 950 L: 1050 H: 2400 (37” x 41” x 102”)

Frame Size - W: 1500 L: 1500 H: 3000 (59” x 59” x 118”)

-

L200

Build Envelope - W: 950 L: 1550 H: 1100 (37” x 61” x 43”)

Frame Size - W: 1500 L: 2000 H: 1500 (59” x 59” x 59”)

L250

Build Envelope - W: 950 L: 2050 H: 1100 (37” x 81” x 43”)

Frame Size - W: 1500 L: 2500 H: 1500 (59” x 79” x 59”)

L300

Build Envelope - W: 950 L: 2550 H: 1100 (37” x 100” x 43”)

Frame Size - W: 1500 L: 3000 H: 1500 (59” x 118” x 59”)

-

C200

Build Envelope - W: 1450 L: 1550 H: 1600 (57” x 61” x 63”)

Frame Size - W: 2000 L: 2000 H: 2000 (79” x 79” x 79”)

C250

Build Envelope - W: 1950 L: 2050 H: 2100 (77” x 81” x 83”)

Frame Size - W: 2500 L: 2500 H: 2500 (98” x 98” x 98”)

C300

Build Envelope - W: 1950 L: 2050 H: 2600 (77” x 81” x 102”)

Frame Size - W: 3000 L: 3000 H: 3000 (118” x 118” x 118”)

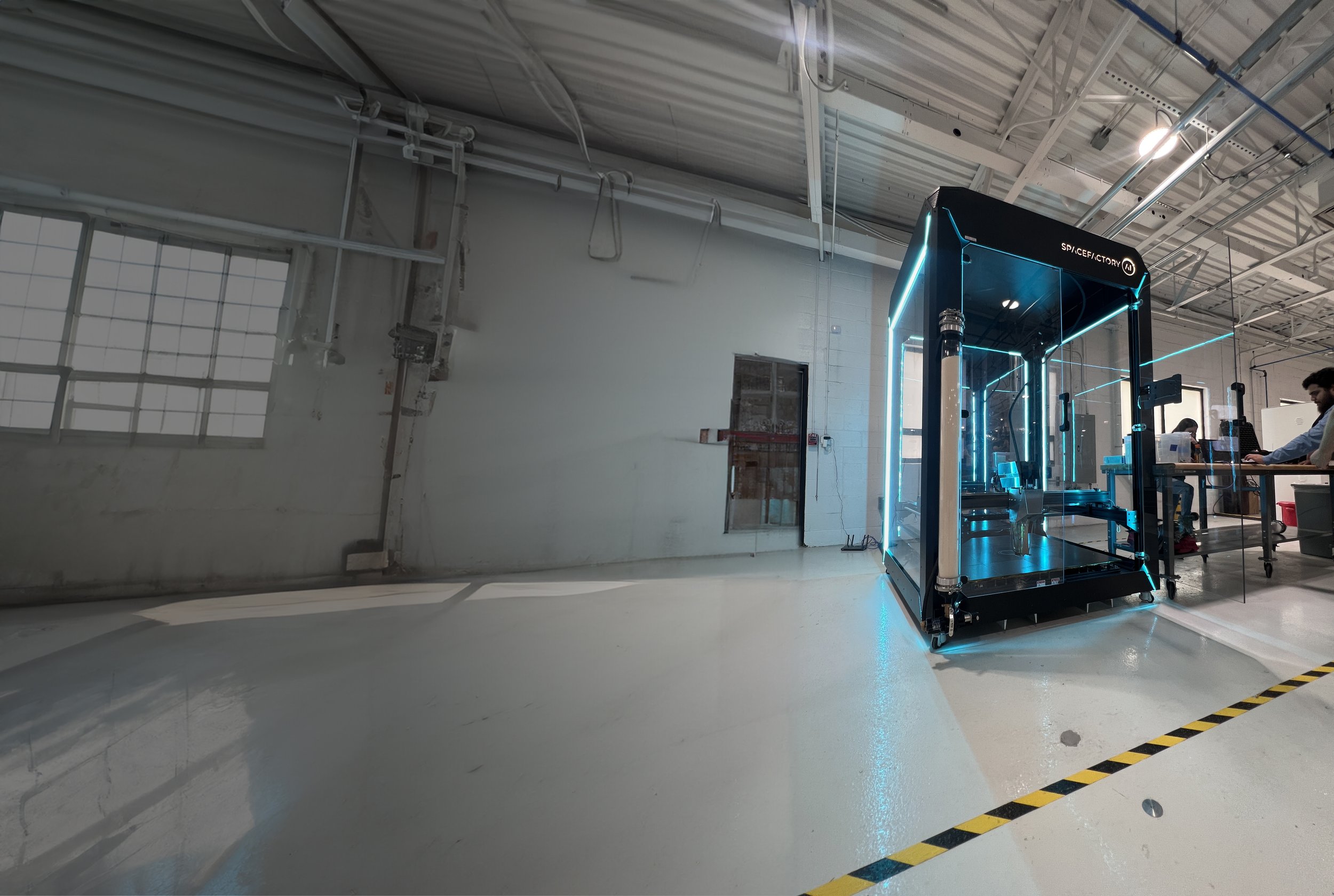

Made in the USA,

from Earth to beyond

Crafted with pride in our Meadowlands facility in New Jersey, every Starforge is a testament to American ingenuity. The “Starforge” story is woven with our collaboration with NASA— a partnership that pushed us to bring space-age solutions down to Earth—including the first ever 3D printer to successfully print in cryogenic vacuum.